“Made in China” was once synonymous with products that were labor intensive, poor quality and knock-offs. It has come a long way since then as China strives to move up the production value chain. To cope with the rising labor wages in China, companies have embraced industrial automation in their factories as a means to boost productivity and efficiency during the manufacturing process.

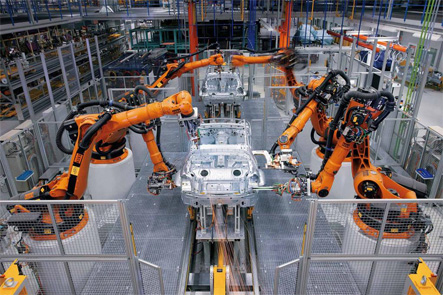

Geely Automotive Plants: The Change from Manual Labour to Industrial Factory Automation

Geely was the first private Chinese car company and I recall visiting Geely’s Shanghai manufacturing plant in 2007. It was a huge manufacturing facility with car parts slung from conveyor belts that pushed the car along the assembly line. Workers were stationed at each point in the assembly line to work on the unfinished car that passed through the factory.

Fast forward to today, that manufacturing process has totally changed as Geely now employs and automates industrial robots to assemble the cars. Robots have replaced workers as they are more precise, tireless and easier to manage.

China: the future of Industrial Automation

The robot industry was once dominated by European and Japanese companies such as Kuka and Kawasaki. Now, even Chinese companies have started to develop their own robotic technology. As shared by the Financial Times, one of the leading companies is Ningbo Techmation which can manufacture robots that are 20-30% cheaper than other international companies.

In the future, “Made in China” will soon represent cheaper, better, and efficient quality industrial automation that powers the world.